|

Hubei Heqiang Machinery Development Limited By Share LTD

|

HQ34 Railway Mobile Bearing Mount/Dismount Press

| Price: | 38000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1) Mobile Structure;

2) Flexible to tranmit to any workplace in the worksop;

3) Easy operation;

4) Imported USA ENERPAC Hydraulic components;

HQ34 RAILROAD MOBILE ROLLING BEARING MOUNT/DISMOUNT PRESS, BEARING PUSHER/PULLER

1. Application scope/Usage:

This Mobile bearing mount/dismount press is applicable to mount/dismount wheelset rolling bearings of different types of domestic/foreign EMU, urben rail transit (Metro,Light rail), coaches with 2~4 brake discs, normal wagons, all types of locomotive and EU trains.

2. Main features:

1) The hydraulic system is integrated on articulated moving lifting trolley, which can realize the integral mounting and dismounting of the rolling bearing;

2) Simple operation, easy to maintain and repair, With sufficient rigidity, excellent static and dynamic performance, and advanced and reliable electrical and control system and reliable safety protection device.

3) All parts, components and accessories of the bearing press are fully new, and manufactured with new high-quality materials. The mechanical components used is a series of advanced, high quality, reliable and practical products, and conforms with relevant international standards. Good performance, suitable for mass production operation.

4) The main oil cylinder, lifting cylinder, manual pump, high pressure micro hydraulic station (including oil tanks, hydraulic valve, hydraulic pump, motor, switch, hydraulic gauge, filter etc.) are the ENERPACK (USA) products. Reasonable heat treatment shall be carried out for key parts and tooling, and effective inspection report shall be issued.

5) Provide a formal safety operation procedure and explain the possible danger situation. The seller shall be responsible for the buyer's personal and property losses caused by the equipment itself.

6) All devices and meters of the bearing press are measured in accordance with the international system of units (SI) standards, and their design and tests conform to international industrial standards (ISO) and International Electrotechnical standards (IEC). The protection level of all electrical components is not less than IP54.

7) All exposed parts of the bearing press should be exposed to corrosion and rust prevention measures; the outer surface of the press should be sprayed with antirust primer and topcoat.

8) The hydraulic system is stable and reliable. The oil cylinder will not fall suddenly under sudden power outages and other special circumstances.

9) The press is with advanced technology, and simple operation, and the wheel set conversion can be realized only by changing the tooling.

3. Technical Parameters:

| Maximum output force | 600KN |

| Effective cylinder stroke | at least 210mm |

| Applicable bearing center height | 400~1000mm |

| Power supply | 380V/50HZ AC 3 phase; 220V/50HZ AC single phase |

| Relative humidity | not more than 95% |

| Ambient temperature | 5ºC~40ºC |

| Noise level during working | less than 70dB |

(*Above parameters are indicaitve and can be modified as per client's actual requirements.)

4. Installation and Commissioning

The Seller is responsible for the installation and commissioning of the machine. If the damage and product quality problem caused during installation and commissioning results in the machine fail to meet the technical agreement and product processing requirements, the machine can be returned or replaced and all the economic losses caused will be borne by the Seller.

5. Technical training

Technical training will be taken place at the user site during installation and commissioning of the press. The manufacturer will be responsible for the technical training of the user's operators, product technicians, CNC programming personnel and Mechanical/electrical maintenance personnel, until they have the abilities of operation, maintenance and programming.

The manufacturer/seller shall provide the training materials for the trainers. The effect of the second technical training shall be signed by the buyer and taken as one main content of the final acceptance.

6. Warranty and After-sale service

The warranty period of the wheel press will be 12 (twelve) months from the date of final acceptance qualified and signed by both parties. During the warranty, the manufacturer will be responsible to repair or replace the damage component caused due to the machine quality. The manufacturer will response within 24 hours after receive the fault notice from the Buyer.

At the end of the warranty, the Seller shall arrange to the user site to carry out a free fully adjustment and maintenance.

After the warranty period, the Seller will provide a wide range of technical support.

The after-sale service includes all aspects, such as mechanical, hydraulic, electronic control, operation, training, software upgrade, etc. The manufacturer will keep in stock for the basic spare parts.

7. Application example

- CRRC Changchun Railway Vehicles Co.,Ltd - WUHAN company;

- Shenyang Liyuan Rail Traffic Equipment Co.,Ltd.;

- Taiyuan Railway Transportation Equipment Co.,Ltd;

- CRRC TAIYUAN CO.,LTD.;

- Guiyang Metro;

- ......

8. Inquiry or questions:

If you have any interests or questions about our machines, please feel free to contact with us by email/Skype or visit our company website, We'll stay online to reply with all points.

COMPANY PROFILE OF HUBEI HEQIANG MACHINERY:

Hubei Heqiang Machinery Development Limited by Share Ltd. was founded in December of 2000. It's located in Ezhou of Hubei province with an area of 40,000 square meters. There are more than 120 employees at present, including 40 professional technical personnel and medium/senior engineers. The company is mainly engaging in the development, manufacture and sales of Rail transit equipment and forging equipment, and providing supporting service for related equipment. After more than 10 years' rapid development, Heqiang Machinery has already grown into the leading manufacturer of rail transit equipment in domesic market. In September of 2016, Heqiang Machinery was successfully listed on "New Third Board" - National SME Share Transfer System, and the stock code is 839214.

Its main products include below series:

1. Rail transit manufacturing and maintenance equipment, mainly includes: Wheelset Press (Mount/Demount, with Double cylinders or Single cylinder), Bearing/Axlebox Press (mount/demount), Wheelset pressure-test machine, Wheelset balancing machine, Gear assembly/disassembly machine, Brake disc assembly machine, Bogie assembly/disassembly machine, Intelligent lifting platform, Wheelset turntable, and other series machine;

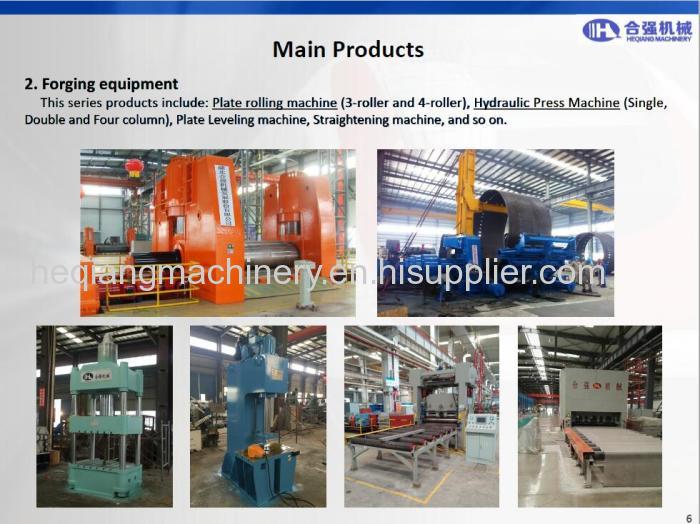

2. Forging equipment, includes:

Plate bending machine, Hydraulic Press Machine, Plate Leveling machine, Straightening machine and uncoiling line;

3. Design and manufacturing of metal construction and non-standard equipment.

With long-term adherence to the quality policy of "Innovative design, Strict control, Elaborate assembly and Customer satisfaction", the company now has nearly 100sets equipment on metal processing, welding and testing, and has initially formed an unique system of device configuration and quality control. It got the certificates of ISO9001:2008, ISO14001:2004 and OHSAS18001-2001. Based on the enterprise spirit of "Transcendence, Perseverance, Integration and Dedication" and the business philosophy of "innovation is the soul, honesty is gold", the company will make use of the advantages of flexible mechanism and strong ability on resources integration to constantly provide users with high-quality products and satisfactory service.

We have already established good business relationship with many customers, such as CRRC and China Railway Corporation etc., also our machines are exported to foreign users, such as Kenya, Myanmar, Vietnam, Indonesia, Malaysia, Saudi Arabia, Iran, Thailand and etc. Till now, we have supplied more than 350sets of rail transit equipment and 600sets of forging equipment.

.jpg)